roughing end mill depth of cut

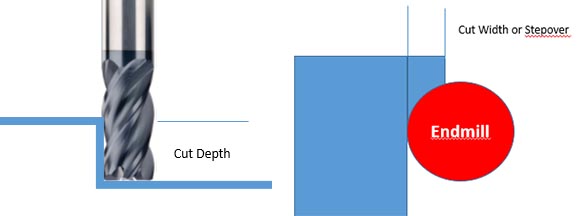

CLICK to browse 32 DEPTH OF CUT MM ROUGHING GENERAL PURPOSE END MILLS made by world class cutting tool manufacturer Guhring. Radial depth of cut RDOC the distance a tool is stepping over into a workpiece.

Optimize Depth Of Cut And Stepover For Better Cnc Milling

With better heat and wear resistance than high-speed steel cobalt steel end mills can run at higher speeds and provide better performance on hard material.

. Multi-Cut HP Roughing. Inches per revolution ipr feed rate of. MRR Axial Depth of Cut Radial Depth of Cut Feed Rate all values in inches or inches per minute for Feed Rate This formula yields the number of cubic inches per minute your cutting.

For this application Ive cut by ordinally 2 or 4 fruit end mills. Due to variable spacing of flutes combined with the NR. I replaced end mill and rerun and see end mill goes in a drilled hole.

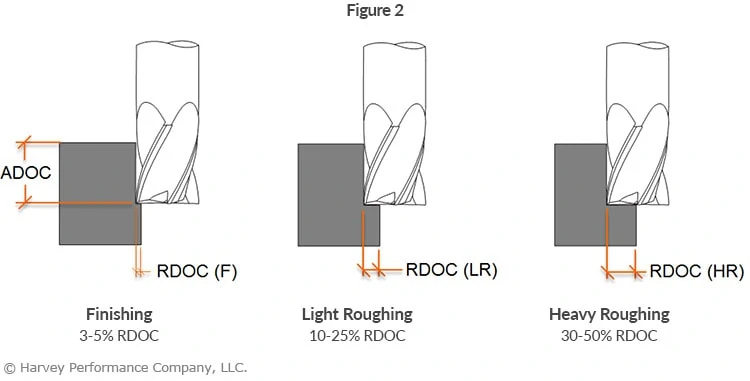

This type of end mill is typically used in roughing applications that require deep cuts and low horsepower. A finer finish will require less depth of cut. The shallow radial stepover enables the deeper cut.

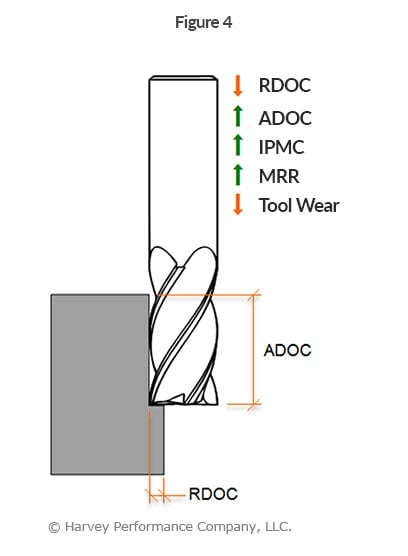

HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. In milling the depth of cut is two-dimensional. Depth of cut plays a critical role in optimized roughing with best results in one pass at 2xD and the full flute length of the end mill.

This means a 050-inch end mill will be engaged 0025 to. Width of Cut maximum amount should not exceed 23 x Cutter diameterSELECTING SPEED AND FEED RATES AND THE DEPTH OF CUT. CLICK to browse 22 DEPTH OF CUT MM ROUGHING GENERAL PURPOSE END MILLS made by world class cutting tool manufacturer Guhring.

Carbide Square End Mills. Widia hanita 5329388 series eccentric rougher 6 flute inch roughing finishing end mill 762 mm max depth of cut 3175 mm dia shank. This spreads wear evenly across the cutting edge dissipates.

My issues is heat trouble. Change geometry - use an end mill with variable flute spacing or a small circular margin. The Radial depth of cut AE or RDOC is the length that the tool engages a workpiece perpendicular to its axis direction and the Axial depth of cut.

The depth of cut is set at values found. The depth of cut of solid end mills needs to be set appropriately according to the machining method workpiece material and cutting edge geometry. This type of end.

This results in lower cutting pressures at a given radial depth of cut. Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. Exactly the end mills are easily burnt out in the application where deep depths of cut.

CLICK to browse 38 DEPTH OF CUT MM ROUGHING GENERAL PURPOSE END MILLS made by world class cutting tool manufacturer Guhring. The following items must be selected by the. Multi-Cut end mills are specifically designed for high-performance roughing operations.

And Axial depth of cut ADOC the distance a tool engages a workpiece along its centerline are the. Running program the other day and i notice broken 58 dia roughing HSS end mill. Work surface looks uneven and feels rough.

Insertable carbide end mills require a certain rather narrow range of depths of cut. This type of end mill also features less wear than its competition. Extra long end mills require a shallower depth of cut because.

For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter.

Rough Milling Speed Vs Power Moldmaking Technology

Speed Feed Recs Melin Tool Company

Diving Into The Depth Of Cut In The Loupe Machinist Blog

End Mill 3 4 4 Flute Roughing M42 Cobalt 5172 Littlemachineshop Com

Basic End Mills Technical Information Msc Industrial Supply Co

Diving Into The Depth Of Cut In The Loupe Machinist Blog

Brief High Feed Contour Ramping Vs High Efficiency Milling Dapra Corporation

Shell End Milling Cutter Turbo 12 Seco Tools Insert Roughing Semi Finishing

End Mill An Overview Sciencedirect Topics

Diving Into The Depth Of Cut In The Loupe Machinist Blog

Basic End Mills Technical Information Msc Industrial Supply Co

Cutting Conditions For Rough Cutting Download Table

Rough Milling Speed Vs Power Moldmaking Technology

High Efficiency Roughing Endmill For Difficult To Cut Material 4 5 6rfh Youtube

Rough Faster With Better Tool Life In Difficult Materials Modern Machine Shop

Iscar Cutting Tools Metal Working Tools Milling Plunging Recessing

Basic End Mills Technical Information Msc Industrial Supply Co